The rumored Nikon Z9 II camera will not be released in 2025, according to the latest information I received.

We need to watch the upcoming Nikon financial earnings report on November 6th, and if the finances are sound, we may not get the Z9II during this Nikon fiscal year (ending March 31st, 2026).

Keep in mind that Nikon may stretch the actual announcement across several phases/months: teaser(s), development announcement, official announcement, and official release, which will make pinpointing a specific date even more difficult.

Announcing the Nikon Z9II camera later will also mean more upgrades – the longer we wait, the better the Nikon Z9II will get.

I haven’t received any reliable rumors about another upcoming Nikon camera. As previously reported, Nikon was expected/rumored to have a slow 2025 year (in terms of new product announcements). Here are the new Nikon products announced so far in 2025:

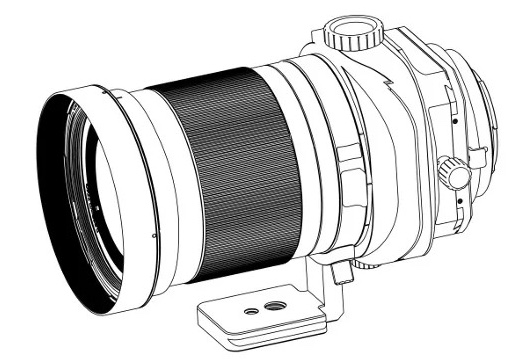

We can expect in 2026 Nikon to concentrate more on video-oriented products (Nikon+RED), including both lenses and cameras.

As usual, if you have any information about the rumored Nikon Z9 II camera, you can contact me anonymously here.